Vacuum press muchina-chakanaka uye chakashata kudzvinyirirwa TM2800/3200

TM2800/3200 Vacuum Press Machine Features

1) Iyo huru furemu inoumbwa nemanganese simbi ndiro yakanyatsogadziriswa, uye gantry milling process haina welding.Chimiro chinonzwisisika, kusimba kwakasimba kuramba, kugadzikana kwepamusoro, kunogona kumira 500 matani esimba rekumanikidza.

2) Nzira yekudziya isanganiswa yemafuta nemagetsi, uye yekumusoro uye yakaderera kudziyisa kaviri.Iyo inopisa ndiro iplate yakakosha yealuminium, iyo inopisa-inobata mafuta inotenderera mukati, uye pasi inopisa.Iyi gadziriso inobudirira inovandudza tembiricha kufanana uye kumucheto kuputira mhando yeplate.Chimiro chepamusoro chebhodhi laminated yakasimba.

3) PLC control system, man-machine interface iri nyore uye iri nyore kushanda.Muchina wepakutanga wakashongedzerwa nemabasa mana, akawanda modes, uye akawanda parameter sarudzo.Sarudzo yemahara chero nguva, yakanakira uye nekukurumidza.

4) Laminate iyo yese yePVC firimu, iyo yekutanga modhi inonyanya kukodzera kugadziridzwa kweakaoma maumbirwo.

5) Pepa rehafu yePVC firimu rinonamirwa, uye iyo yekudzoreredza modhi yakakodzera kuzadzazve mahwendefa madiki.

6) Namira iyo yose yePVC firimu, iyo yekubatanidza modhi, unogona kusarudza inoenderana modhi zvinoenderana nekusiyana kwezvinhu: inoyangarara modhi, composite mode, matte modhi, yakakwirira-gloss mode.

7) Namira iyo yose yePVC firimu, simbisa maitiro, basa iri haridi silicone ndiro, uye yepakati control frame inofanira kubviswa.Inokodzera yakakwirira-giredhi inopenya PVC film lamination.

Kurumidza kudzvanya furemu

Hubble lenses anogadzirwa kubva kumusoro-giredhi methafilcon A hydrogel zvinhu.Iine 55% yemvura yemukati, UV dziviriro, uye mupendero mupendero, iwo akagadzirirwa kuiswa nyore, kunyaradza kwemazuva ese uye nekristaro yakajeka kuona.

Control Panel

Iyo yekushanda interface inodzorwa nedhijitari kuratidzwa, iri nyore kunzwisisa. Pamusoro peiyo, maererano nePVC firimu rezvinhu zvakasiyana, gadzirisa inowirirana paramita (parameter tafura inopihwa kutariswa kana uchibuda mufekitori), muchidimbu, ingo dzvanya bhatani rekutanga paunenge uchishanda, iro rinokurumidza uye rinochengetedza nguva.

High speed yakananga yekubatanidza mota

Iyo worktable inomhanya nepamusoro-kumhanya yakananga-yakabatana mota dhiraivha uye fequency control.Naizvozvo, nzira yekudzikisira uye kumira pakumhanya zvakanyanya inodzivirira kuti ndiro iendeswe.Mukuwedzera, inopfupisawo nguva yekumhanya uye inovandudza kushanda zvakanaka.

Pipeless yekubatanidza mudziyo

Kuti ujekese, kurongeka kwepipeless connection device inogadzirisa matambudziko maviri: 1. Mumamiriro ekunze ekunze, iyo tsika yesimbi simbi hose iri nyore kuputsa nokuti haipikisane nechando;2. Yechinyakare vacuum simbi pombi ine refu refu kupfeka uye abrasion, Nyore kukwenya uye kukonzera mhepo kuvuza.

Inoyangarara ichidziya nzira

Inoshongedzera nebasa rekuyangarara nekudziya kwePVC firimu, iro rinogona kugadzirisa chiitiko chemakwinya kana nzvimbo ine shaded pane yepakati uye yakaderera giredhi yakapfava PVC firimu, uye inovandudza kufanana kwekupisa pamusoro pePVC firimu.

High speed vacuum pombi

Inoshongedzerwa nepombi yevacuum inomhanya-mhanya ine spidhi yakayerwa ye100m3/h (inoda) uye tangi yevacuum yakakura.Naizvozvo, kumanikidzwa kunodiwa kunogona kusvika munguva pfupi, uye kumhanya kwepombi kunokurumidza.Saka, pfupisa nguva yekuumba uye uvandudze kushanda zvakanaka.

Special electric aluminium plate

Yakashongedzerwa neyakagadziridzwa magetsi ekudziya aluminium ndiro yekudziya, nekukurumidza kupisa uye yunifomu kupisa mwaranzi.Yakashongedzerwa neyemhando yepamusoro aluminium silicate board insulation, kupisa kupisa uye kusapinda nemoto, uye thermal insulation effect yakanaka.Kushanda pane imwe nguva tembiricha inokunda dambudziko rekusiyana kukuru kwekushisa uye kushandiswa kwesimba kwakanyanya.

Nhanganyaya

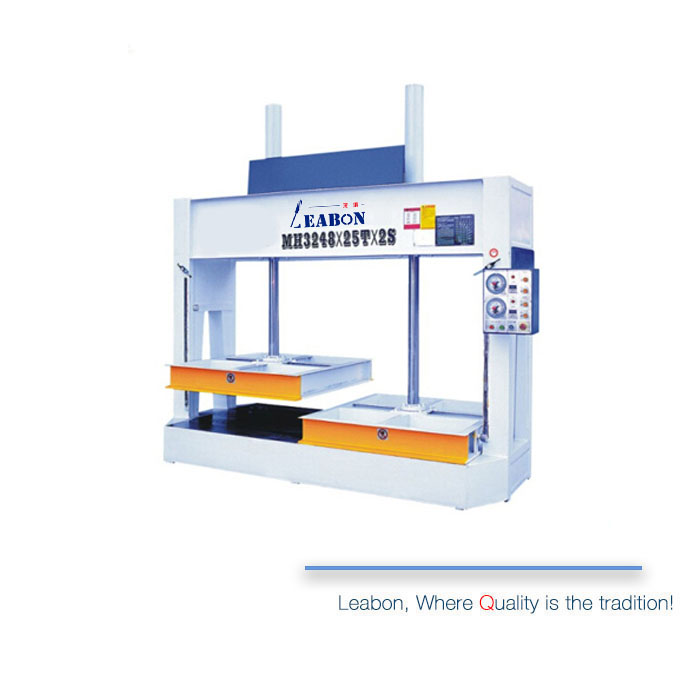

Kuunza yedu TM yakatevedzana yakanaka uye isina kunaka kudzvanywa yakasarudzika-yakaumbwa firimu mashini, mhinduro yakakwana yekuputira yepamusoro-giredhi PVC uye kutamisa mafirimu pamabhodhi akasiyana emapuranga.Yakagadzirirwa chaizvo indasitiri yekushongedza imba yekushongedza, yedu vacuum press machine inoshandiswa zvakanyanya mukugadzira makabati, magonhi ane hinged, magonhi ekabhati yekugezera, matafura emakomputa, uye fenicha yehofisi.

Yedu TM2800/3200 modhi dzakashongedzerwa neakakosha maficha ane chokwadi chekuvandudza kunaka uye kugadzirwa kweiyo lamination process.Iyo furemu yakagadzirwa nemanganese simbi ndiro uye inogadziriswa negantry milling tekinoroji.Iko hakuna mawelds, uye chimiro chayo chinogona kubata kusvika ku500 matani esimba rekumanikidza, zvichiita kuti igare yakasimba, yakatsiga, uye yakavimbika.

Nzira yedu yekudziya inoshandisa mafuta nemagetsi kudziya mbiri kumusoro uye pasi peiyo yakakosha aluminium ndiro.Iwo kupisa conduction mafuta anotenderera mukati uye zvinobudirira kuvandudza tembiricha kufanana uye hemming mhando yebhodhi, zvichikonzera kune yakawedzera textured surface laminate.

Iyo PLC yekudzora sisitimu inoratidzira iri nyore kushandisa man-muchina interface ine akawanda modes uye paramita kusarudza kubva.Iwo mana ekushandisa modhi inobvumira kuita kwakasiyana-siyana mulamination, kusanganisira iyo yese PVC firimu, laminate hafu yechidimbu, uye namatidza firimu rose rePVC mukuyangarara, composite, frosted, kana kuratidza maitiro.

Nemichina yedu yevacuum press, unogona kuwana mibairo yakanaka nechero rudzi rwezvinhu uye chimiro.Iyo yose yePVC film lamination yakakwana pakugadzirisa maumbirwo akaomarara, nepo kudyisa hafu yechidimbu chePVC firimu kwakakodzera mabhodhi madiki.Nekushandisa iyo yese PVC firimu mune yakasarudzika modhi, unogona kubvisa kudiwa kwesilicone ndiro uye yepakati control furemu.

Muchidimbu, yedu TM yakatevedzana yakanaka uye isina kunaka kudzvanywa yakasarudzika-yakaumbwa firimu mashini inokwanisika uye yakavimbika mhinduro kune ako lamination zvaunoda.Bata nesu nhasi kuti udzidze zvakawanda nezve zvigadzirwa zvedu uye kuti tingabatsira sei kuvandudza maitiro ako ekugadzira.

ZVIMBO VEDU

| Model | TM2800 | TM3200 |

| Zviyero zvekunze | 10800*2150*2100mm | 12000*2150*2100mm |

| Tafura saizi | 2600*1300*30mm | 3000*1300*30mm |

| Processing urefu | ≤40mm | ≤40mm |

| simba rose | 47kw | 56kw |

| Avhareji yekushandisa simba | 10kw/h | 10kw/h |

| Huremu hwese | 14000kg | 16500kg |

| Air supply system uye air pressure | ≥1.5m³ / 0.8Mpa | ≥1.5m³ / 0.8Mpa |

| Kupisa kaviri kumusoro nekudzika | 25.2kw / 14.4kw | 28.8kw / 16.8kw |

| Mhanya injini | 0.55kw×2 | 0.55kw×2 |

| Pombi yemafuta ekupisa kupisa | 0.4kw | 0.4kw |

| High-speed vacuum pombi | 2.2kw / yakatemerwa kupomba kumhanya 100m³/h | 2.2kw / yakatemerwa kupomba kumhanya 100m³/h |

| Hydraulic system | Low pressure 3kw, high pressure 1.5kw | Low pressure 5.5kw, high pressure 1.5kw |

| Hydraulic pressure | Low pressure 4Mpa / High pressure 20Mpa | Low pressure 4Mpa / High pressure 25Mpa |

| Kumanikidzwa kwefirimu | 0.4Mpa | 0.4Mpa |

| Kudzora System | PLC-OMPON | PLC-OMPON |

| Mafuta ekutamisa kupisa | 320# | 320# |

| Hydraulic mafuta | 68# | 68# |

| Automatic film cutter | Yekutanga 2 seti | Yekutanga 2 seti |

| Main frame structure | 3 seti yeakakosha simbi ndiro, 6 seti yemasilinda emafuta, mafuta-magetsi hybrid | 4 seti yeakabatanidzwa simbi ndiro, 8 seti yemasilinda eoiri, mafuta-yemagetsi hybrid |